01: Ex/Explosion

Why explosion protection?

Explosive Substances : Many production sites produce certain combustible substances. About two-thirds of underground coal mines have explosive substances; in the chemical industry, more than 80% of the production plant area has explosive substances.

Oxygen: Oxygen in the air is everywhere.

Ignition source: In the production process, the use of a large number of electrical instruments, a variety of friction sparks, mechanical wear and tear sparks, electrostatic sparks, high temperatures and so on unavoidable, especially when the instrumentation, electrical failure.

When the concentration of explosive substances mixed with oxygen is within the explosive limit, if there is an explosive source, an explosion will occur. Therefore, it is necessary to take explosion-proof.

Format of Explosion Protection Marking

Usually factories or mining areas of explosive hazardous media, according to its ignition energy, the minimum ignition temperature and the presence of explosive hazardous gases at the scene of the time cycle of scientific classification and grading to determine the explosion-proof equipment explosion-proof signs and explosion-proof shape.

Explosion-proof electrical equipment according to GB3836 standard requirements, explosion-proof equipment marking content includes = explosion-proof form + explosion-proof grade + electrical category + temperature group + equipment protection level.

We can match the corresponding explosion-proof level according to the logo on the equipment, such as

ExiaⅡCT4Ga = ia (intrinsically safe) + IIC (MESG ≤ 0.5) + T4 (135 ℃ <t ≤ 200 ℃) + Ga (explosive gas environment, zone 0).

Ex explosion-proof type:

Ex d, Ex e, Ex p, Ex i(Ex ia, Ex ib), Ex o, Ex q, Ex m, Ex n, DIP(DIP A, DIP B), Ex s

Ex ia class (zone 0-2), the highest level of explosion protection:

Electrical equipment that cannot ignite explosive gas mixtures during normal operation, one failure and two failures.

For normal operation, the safety factor is 2.0;

For one fault, the safety factor is 1.5;

For two faults, the safety factor is 1.0.

In normal operation, sparking contacts with explosion-proof enclosure, gas-tight enclosure or doubled must be added to increase the safety factor.

Ex ib Class (Zone 1-2):

Electrical equipment that cannot ignite explosive gas mixtures during normal operation and one fault.

The safety factor for normal operation is 2.0;

A safety factor of 1.5 for a fault.

In normal operation, sparking contacts must be protected by explosion-proof or gas-tight enclosures, and there must be means of self-indicating faults.

Type of electrical equipment:

Class Ⅰ: electrical equipment for coal mine and underground;

Class II: electrical equipment for all other explosive gas environments other than coal mines and underground.

Class III: Electrical equipment for explosive dust environments other than coal mines.

According to the maximum experimental safety gap (MESG) or the minimum ignition current (MICR) to distinguish, Class II can be divided into: IIA, IIB, IIC three categories (the larger the gap, the lower the environmental risk)

(MESG)mm

IIA 0.9≤MESG

IIB 0.5<MESG<0.9

IIC MESG≤0.5

Temperature group :

According to the explosive gas mixture according to the difference in ignition temperature, the group is divided into T1, T2, T3, T4, T5, T6 six, the ignition temperature is expressed in t (℃), the maximum permissible surface temperature of each group (the lower the temperature is better) are:

T1:450℃<t

T2:300℃<t<450℃

T3:200℃<t≤300℃

T4:135℃<t≤200℃

T5:100℃<t≤135℃

T6:85℃<t≤100℃

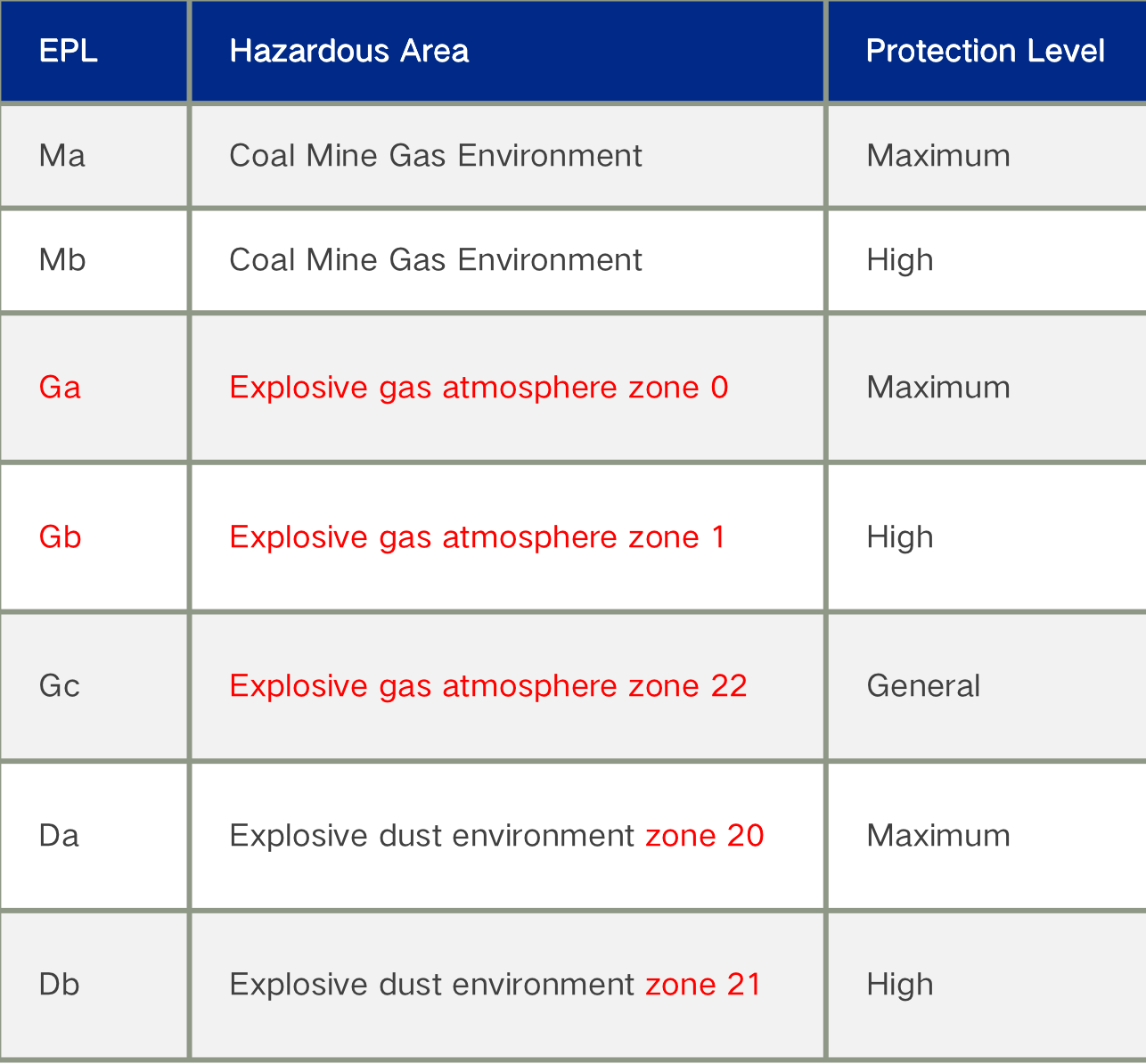

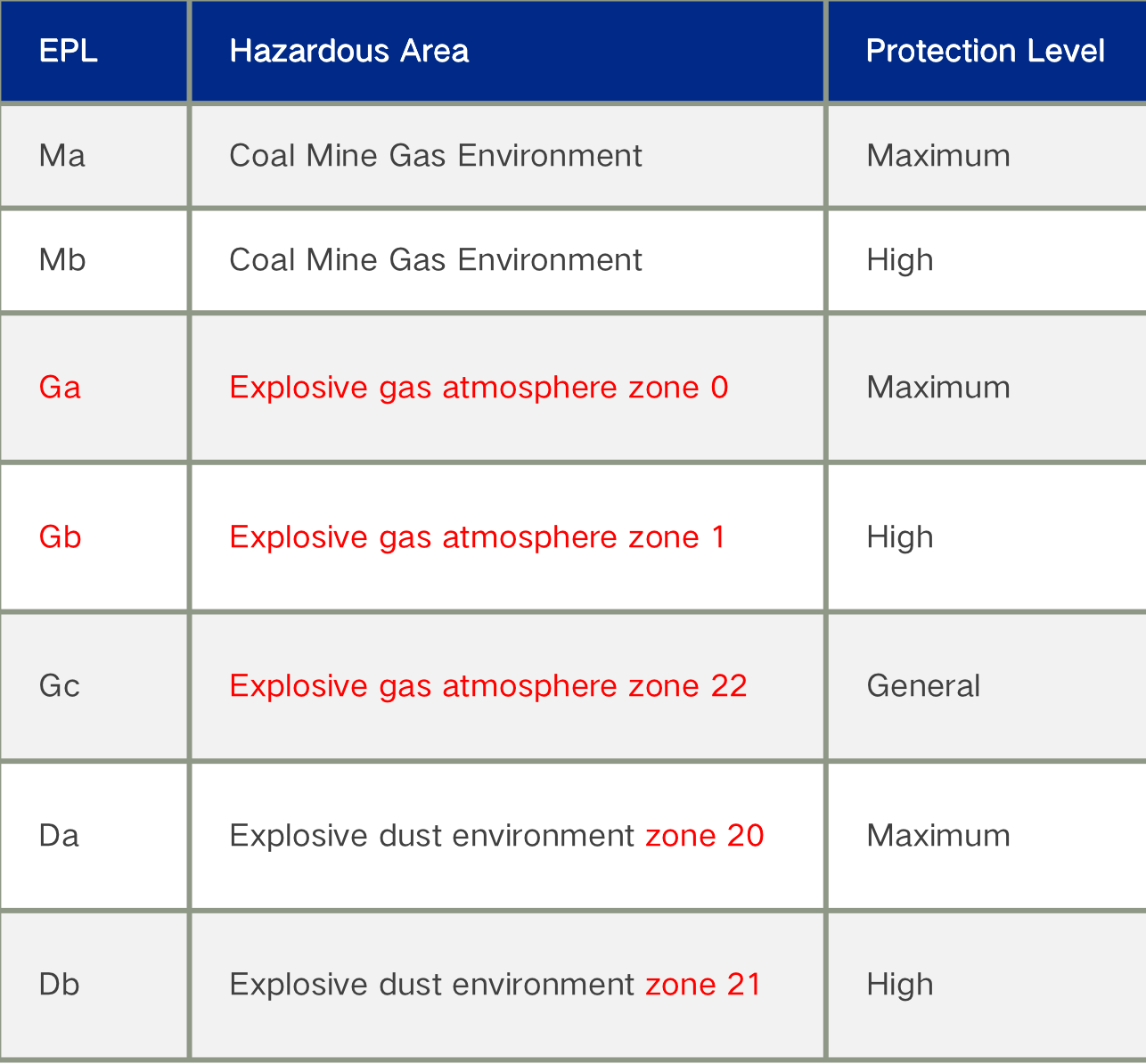

EPL(equipment protection level):

The level of protection for equipment based on the likelihood of the equipment becoming a source of ignition and the different characteristics of explosive gas environments, explosive dust environments and explosive environments in coal mines.

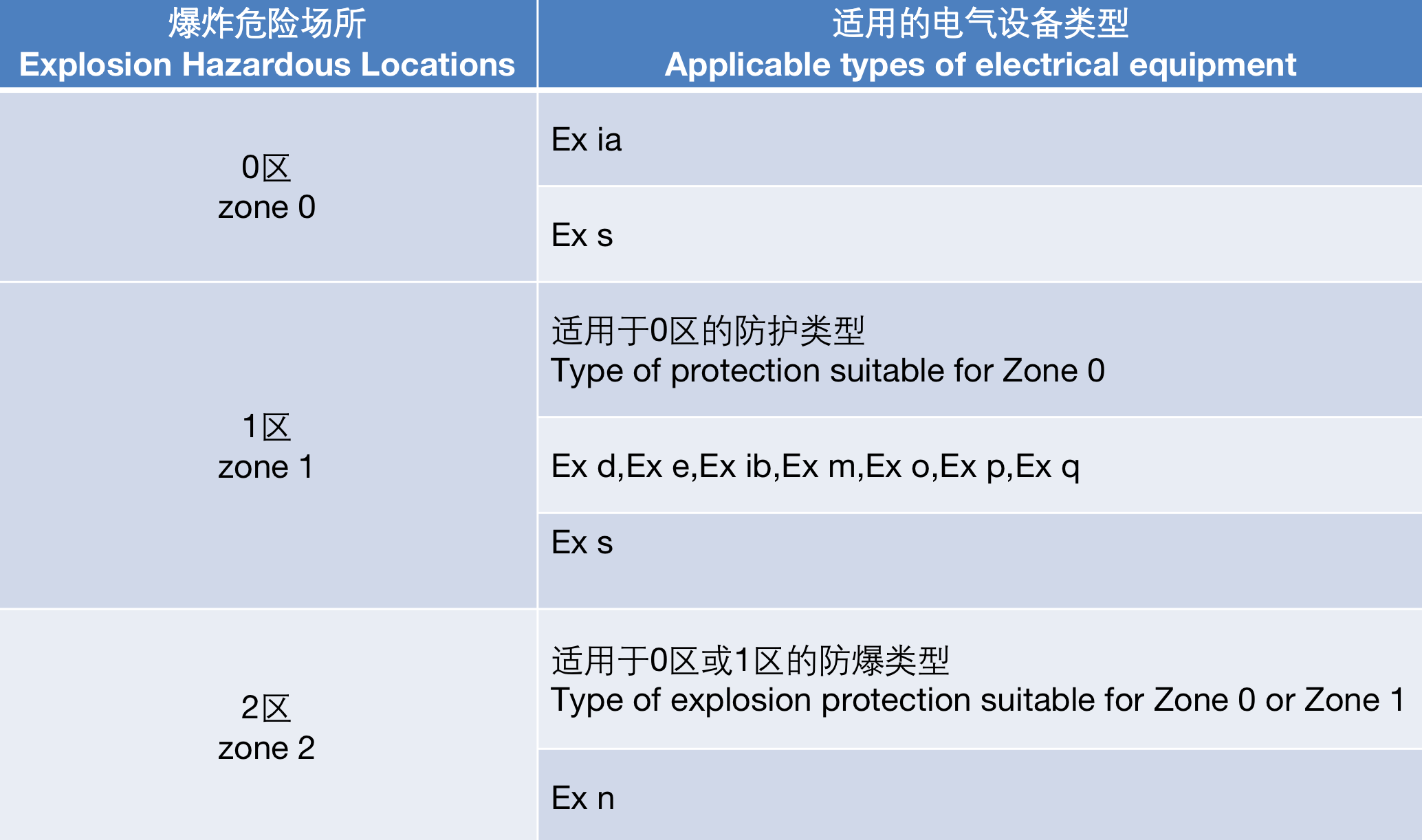

Explosive gas environment:

Zone 0: explosive gas environment continuous or long-term existence of the place;.

Zone 1: explosive gas environment may occur during normal operation of the place; and

Zone 2: explosive gas environment is unlikely to occur during normal operation, and if it does occur, it will occur occasionally and for a short period of time.

Explosive dust environment.

Zone 20: the air in the combustible dust clouds appear continuously for a long time often appear to form an explosive environment in the area.

Zone 21: Normal operation, the air may occasionally appear in the combustible dust cloud to form an explosive environment in the region.

Zone 22: Normal operation, the air in the combustible dust cloud is unlikely to appear, if it occurs, only a short period of time to form the explosive environment of the region.

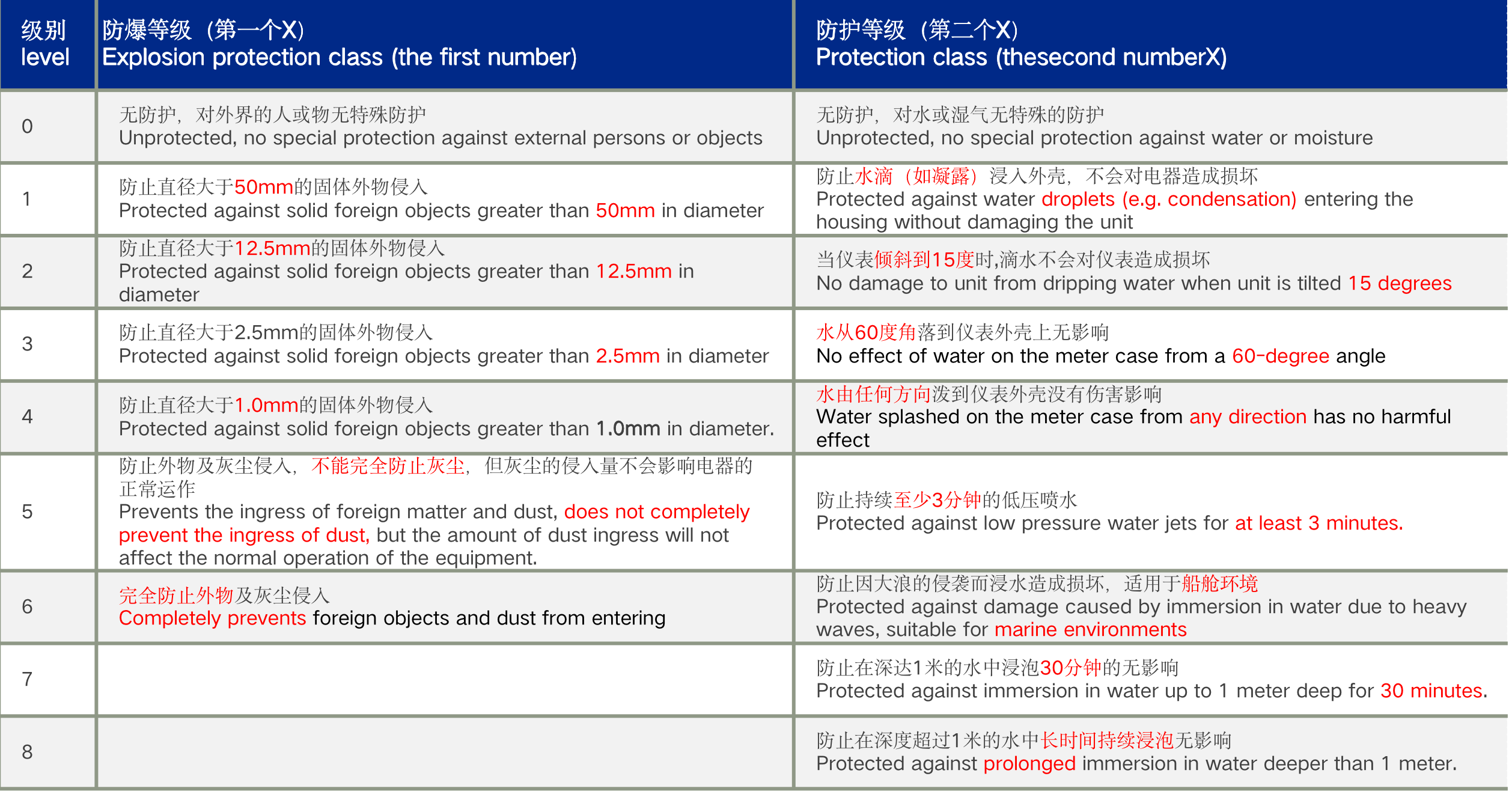

02: IPXX / INGRESS PROTECTION

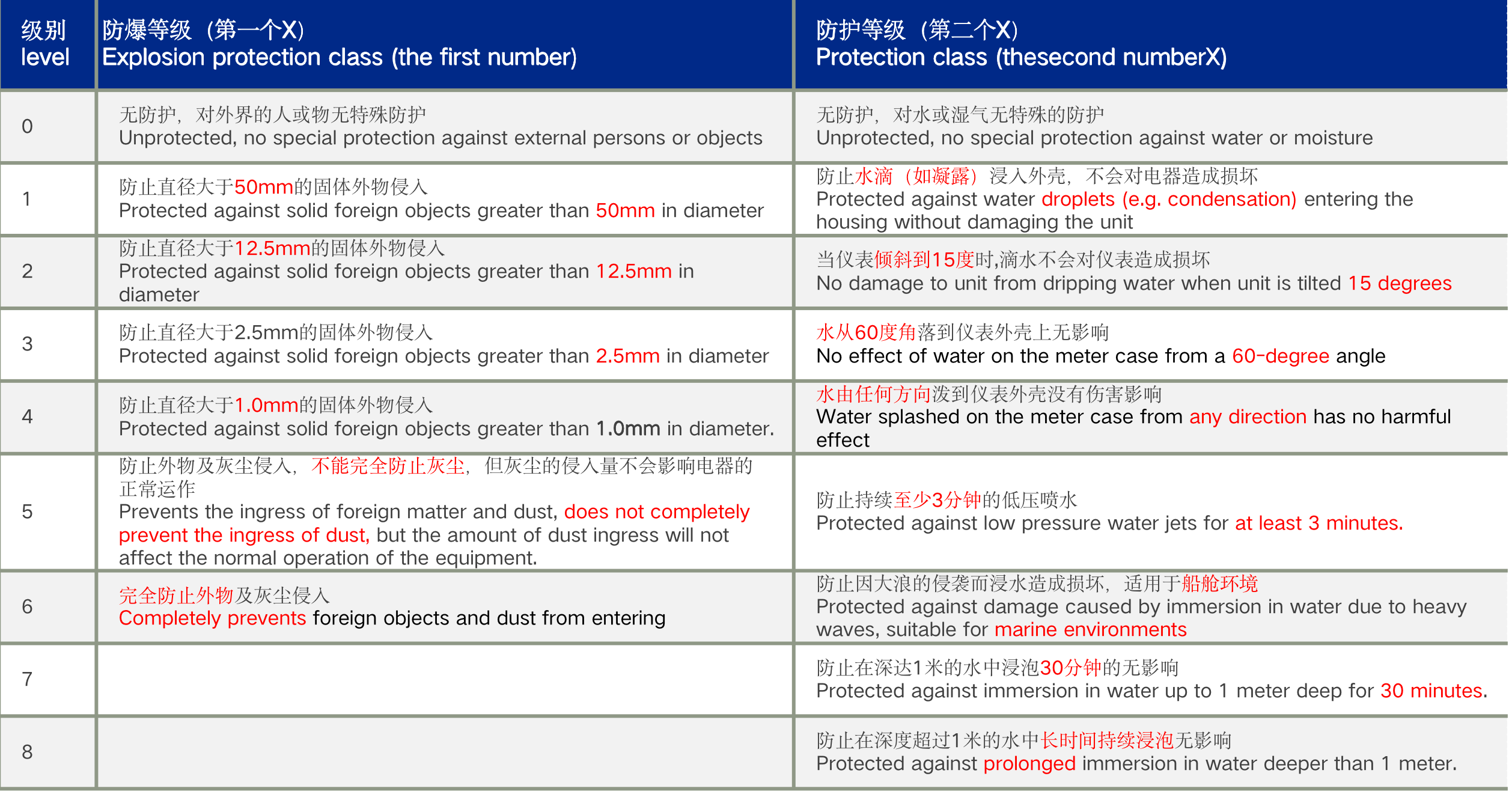

The IP (INGRESS PROTECTION) system is designed by IEC (International Electrotechnical Commission). The electrical equipment to be classified according to its dust and moisture characteristics, here referred to as foreign objects including tools, human fingers, etc., cannot touch the electrical equipment within the charged part to avoid electric shock.

The IP protection level is composed of two numbers, the first number indicates that the device is free from dust and prevents the ingress of foreign objects, and the second number indicates that the device is sealed against moisture and water ingress, and the larger the number, the higher the protection level.

Example: The display meter is labeled IP65, which means that the product is completely protected against dust ingress and can be rinsed with water without any harm.

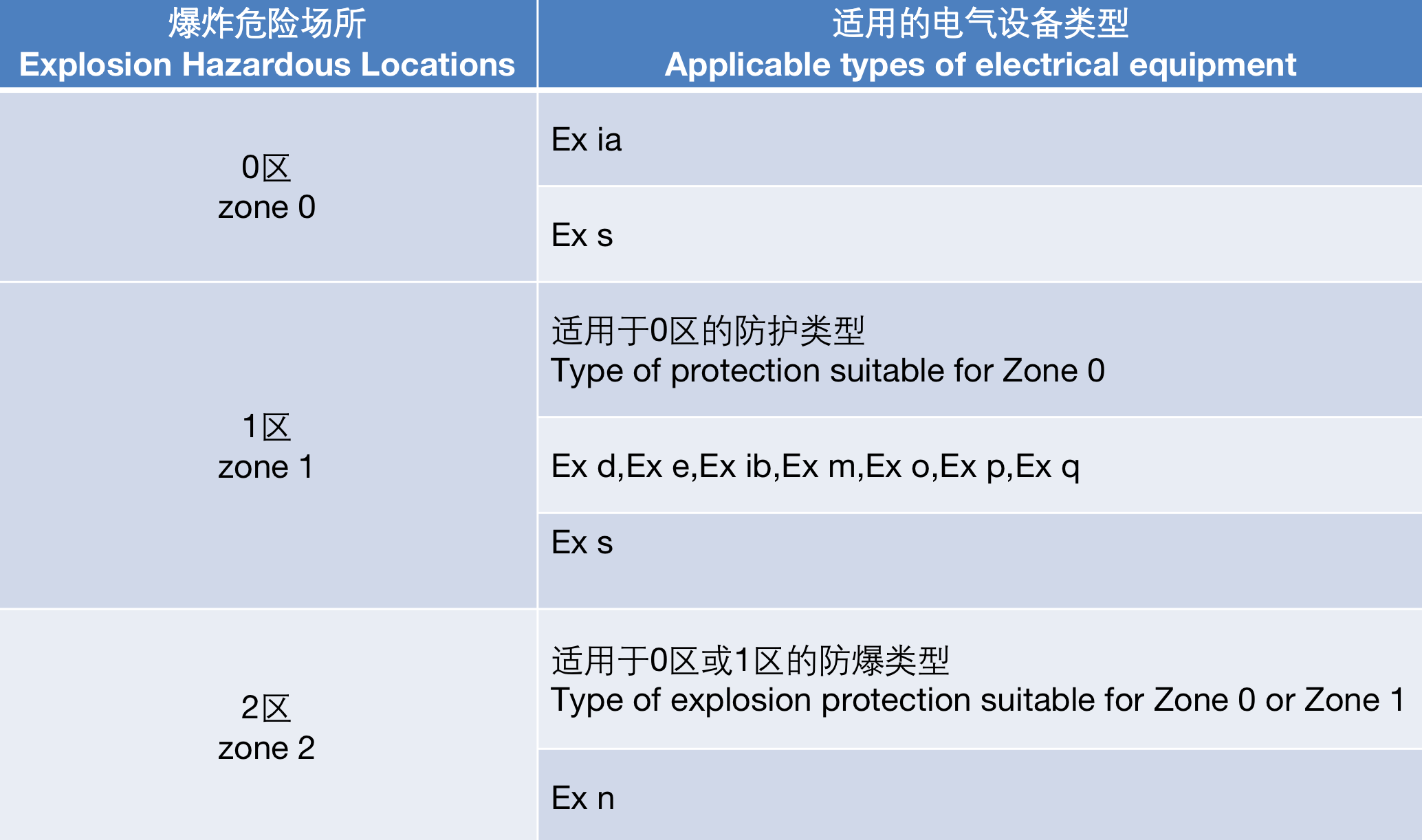

03: Selection principle of gas detector

1.according to the results of the gas explosion hazardous areas to choose the explosion-proof instrumentation explosion-proof type;

2.according to the gas explosion hazardous areas of explosive gases and vapors may occur in the explosion level of explosion-proof instrumentation to choose the explosion-proof level;

3.according to the gas explosion hazardous areas of explosive gases and vapors may occur in the spontaneous combustion temperature selection of explosion-proof instrumentation temperature group.

Special emphasis: Class 0 area is only allowed to use ia class intrinsically safe detector and other electrical equipment specially designed for class 0 area (special type "s").

There are three kinds of explosion-proof external boxes available in our company (corrosive background gas is recommended to use stainless steel explosion-proof external box).

To purchase gas analysis equipment and gas detection one-stop solution and get more gas industry news and science, please contact us!