- Home

-

Products

- ⦁ Gas Detectors---Portable Single Gas Detectors Personal Gas Monitors Multi-Gas Detectors Area Monitors Accessories

- ⦁ Gas Detectors---Fixed Gas Transmitters UV Flame Gas Detectors Controllers

- ⦁ Gas Analyzers Syngas Analyzers Flue Gas Anlyzers Biogas Analyzers CEMS (Continuous Emission Monitoring System) Ozone analyzer

- ⦁ Natural Gas Detectors Remote Laser Mathane Detector Natural Gas Leak Survery Equipment Software

- ⦁ Particle Counters Portable Particle Counters Cleanroom Online Particle Counters Biological Air Samplers Photometers and other equipments Accessories

- ⦁ Air Quality Monitoring System Ambient Air Quality Monitoring Station Air Pollution and VOC Emissions Monitoring Stations

- ⦁ Pharmaceutical Monitoring Equipment Filter Integrity Tester Glove Integrity Tester TOC Analyser Package Integrity Tester Liquid Particle counter

-

Solutions

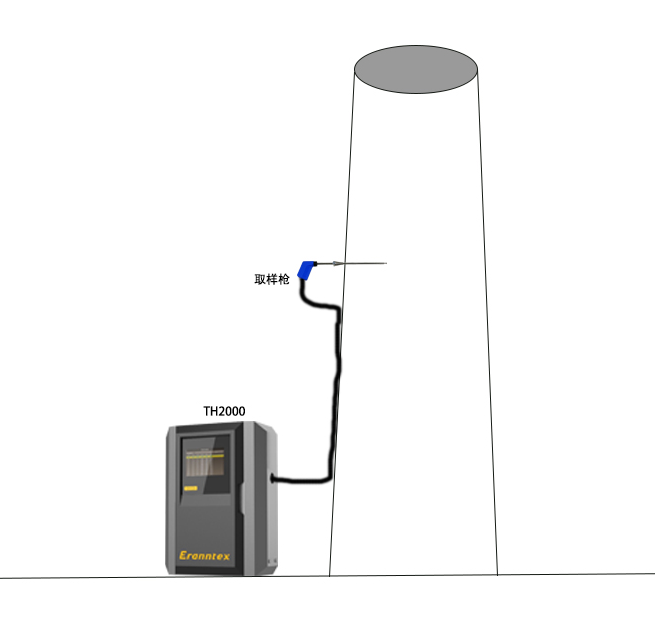

- TVOC Online gas monitor solution

- Energy chemical industry

- Municipal engineering

- Environmental protection

- Electronic appliances

- Food health

- Other

Solutions

Zetron Techonology is a professional company of committed to the development of the gas detection industry, has more than 15-year experience in specializing in the research, development, manufacture and sale of gas detectors.

-

Certificates

Certificates

Beijing Zetron Technology Co., Ltd is an international enterprise focused on providing professional gas detection solutions.

-

News

News

Zetron Techonology is a professional company of committed to the development of the gas detection industry, has more than 15-year experience in specializing in the research, development, manufacture and sale of gas detectors.

-

About Us

About Us

Beijing Zetron Technology Co.,Ltd is a professional company of committed to the development of the gas detection industry, has more than 15-year experience in specializing in the research, development, manufacture and sale of gas detectors.

- Contact

- Customer Case

- Product Brochure